1.4571 || 316Ti

Stainless austenitic chromium-nickel steel

The material 316 Ti is a stainless austenitic chromium-nickel steel which is characterised by its increased resistance to corrosion as well as pitting. Its corrosion properties are roughly comparable with those of material number 316. The stainless steel has good resistance to most acids – apart from hydrochloric acid and sulphuric acid –, even at high concentrations and temperatures.

Compared to titanium-unstabilised steels, 316 Ti has better resistance to intergranular corrosion. The addition of titanium prevents the precipitation of chromium carbides in the grain boundaries during long-term heating in the temperature range of about 450 – 850 °C.

Stainless steel

- Good weldability

- High resistance to general corrosion

- Good resistance to intergranular corrosion

- Good cold formability

- High tensile strength

- Good forgeability

316 Ti applications

- Chemical industry

- Plant engineering

- Food industry

- Tank and apparatus engineering

- Petrochemical industry

- Pulp / Paper industry

Chemical values – Reference analysis (weight proportion in %)

| Value | Proportion % |

|---|---|

| C | ≤ 0,08 |

| P | < 0,045 |

| S | ≤ 1,0 |

| Si | 0,7 |

| Mn | ≤ 2,0 |

| Cr | 16,5 – 18,5 |

| Mo | 2 – 2,25 |

| Ni | 10,5 – 13,5 |

| N | ≤ 0,8 |

Mechanical values at room temperature

| Tensile strength N/mm² | 500 – 730 |

| Tension elastic limit Rp 0,2 N/mm² | ≥ 190 |

| Breaking elongation A5 % | 35 |

Standards

- Designation according to DIN: X 6 Cr Ni Mo Ti 17

- ASTM Grade: 316 Ti

- EN: 1.4571

- ASME: 316 Ti

- AFNOR: X6CrNiMoTi 17-12-2

- DIN: 1.4571

- SIS: 2350

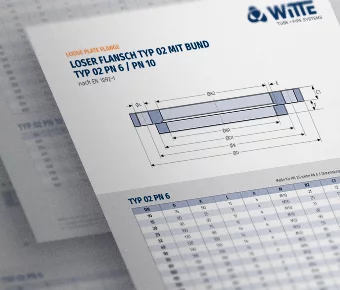

Tables and rates

Scope of delivery

Haven’t found the right steel?

We offer you the complete range for stainless steel piping systems, in different materials and for the highest demands.