1.4547 || 254SMO || S31254 || F44

High-alloy austenitic stainless steel for use in seawater

254 SMO is a high-alloy austenitic type of stainless steel, generally known for its ideal use in the shipping sector in contact with seawater as well as in saline and sulphurous environments. It was developed for use in seawater and other aggressive chloride-containing media, up to food industry applications, and belongs to the super-austenite group. The increased molybdenum content and the addition of nitrogen provide excellent resistance to pitting and crevice corrosion.

Special stainless steel

The steel is characterised by the following properties:

- Excellent resistance to pitting and crevice corrosion, PREN = ≥42,5

- Higher strength than conventional austenitic stainless steels

- Good weldability

- High resistance to general corrosion

- High resistance to acidic solutions

- High resistance to stress corrosion

254 SMO applications

- Chemical industry

- Petrochemical industry

- Pulp / Paper industry

- Sea and seawater plants

- Flue gas systems / Scrubbers

- Shipbuilding / Offshore

- Food industry

Chemical values – Reference analysis (weight proportion in %)

| Value | Proportion % |

|---|---|

| C | ≤ 0,02 |

| P | ≤ 0,03 |

| S | ≤ 0,01 |

| Si | ≤ 0,7 |

| Mn | ≤ 0,03 |

| Cr | 19,5 – 20,5 |

| Mo | 6 – 7 |

| Ni | 17,5 – 18,5 |

| Cu | o,5 – 1 |

| N | 0,18 – 0,25 |

Mechanical values at room temperature

| Tensile strength N/mm² | 650 – 850 |

| Tension elastic limit Rp 0,2 N/mm² | ≥ 300 |

| Breaking elongation A5 % | 35 |

Assignment to current and older standards

- Designation according to DIN: X 1 Cr Ni Mo Cu N

- EN: 1.4547

- UNS: S 31254

- VdTüV: 473

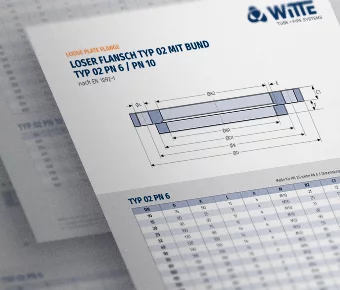

Tables and rates

Scope of delivery

Haven’t found the right steel?

We offer you the complete range for stainless steel piping systems, in different materials and for the highest demands.