1.4541 || 1.4878 || 321 || 321H

Stainless austenitic chromium-nickel steel stabilised with titanium

The material 321 is a stainless austenitic chromium-nickel steel which has excellent resistance to aggressive media. Due to the balanced proportion of chromium and nickel, the steel has an austenitic structure. It offers good oxidation resistance in air up to about 900 °C; when operated in carbon dioxide, it is 650 °C.

Stainless steel

- Good weldability

- Good resistance to general corrosion *Good resistance to intergranular corrosion

- Good cold formability

321 || 321 H applications

- Chemical industry

- Plant engineering

- Food industry

- Tank and apparatus engineering

- Petrochemical industry

- Pulp / Paper industry

Chemical values – Reference analysis (weight proportion in %)

| Value | Proportion % |

|---|---|

| C | ≤ 0,08 |

| P | < 0,045 |

| S | ≤ 0,03 |

| Si | ≤ 1,0 |

| Mn | ≤ 2,0 |

| Cr | 17 – 19 |

| Ni | 9 – 12 |

| Ti | ≤ 0,8 |

Mechanical values at room temperature

| Tensile strength N/mm² | 500 – 730 |

| Tension elastic limit Rp 0,2 N/mm² | ≥ 180 |

| Breaking elongation A5 % | 35 |

Assignment to current and older standards

- Designation according to DIN: X 6 Cr Ni Ti 18-10

- ASTM Grade: 321 / 321H

- EN: 1.4541

- ASME: 321/321H

- AFNOR: X6CrNiTi 18-10

- DIN: 1.4541

- SIS: 2337

- UNS: S32100

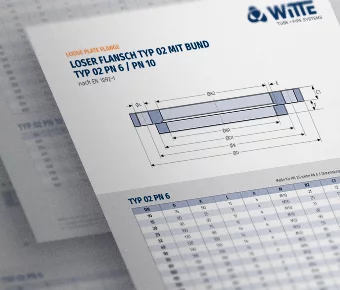

Tables and rates

Scope of delivery

Haven’t found the right steel?

We offer you the complete range for stainless steel piping systems, in different materials and for the highest demands.