As a specialist in stainless steel pipes, fittings, and flanges, we offer a wide range of collars and stub ends in various designs. Our products are ideally suited for professional plant engineering, the chemical industry, equipment manufacturing, and many other sectors with high demands on quality, safety, and corrosion resistance.

What Is a Collar?

A collar is a mechanical forming at the end of a pipe, where the pipe is expanded and flared outward to form a tight and secure connection with a matching loose flange. The collaring process enables strong, detachable connections without welding or soldering. The combination of a stainless steel collar and a corresponding flange ensures excellent pressure and temperature resistance.

Stainless Steel Collars for Flanged Connections – Precise, Stable, and Corrosion-Resistant

We offer stainless steel collars in a wide range of variants. Our collars and stub ends are compatible with common international standards such as:

● EN 1092-1 / Type 37

● ASME B16.9 / MSS SP 43

● DIN 2642

Manufacturing is carried out using high-quality materials – including standard stainless steels such as 1.4541 (321) and 1.4571 (316Ti), as well as special alloys like:

● 1.4462 (Duplex S31803 / S32205) – austenitic-ferritic, especially corrosion-resistant

● 1.4410 (Super Duplex S32750) – for extreme industrial requirements

● 1.4878 (X10CrNiTi18-10) – ideal for thermally stressed applications

Short-term production from bar stock is also possible for custom dimensions or urgent projects.

Types of Collars for Every Application

We stock a broad range of collar types: from the classic 37° collar fitting according to DIN, to specialized versions in line with ASME standards. All components are technically approved and certified according to internationally recognized norms.

Certifications for Collars (Collar Pipe Ends and Collar Components):

● MSS-SP 43 – Stainless steel butt-weld fittings for low/medium pressure

● ASME B16.9 – Factory-made steel pipe fittings (Short/Long Pattern)

● ASME SA 815 / SA 403 – Forged stainless steel fittings

● ASME SB 366 – Fittings made of corrosion- and heat-resistant alloys

● Beveled ends in accordance with ASME B16.25 – for weld-ready preparation

Certifications for Stub Ends:

● MSS-SP 43 – Stainless fittings for low to moderate pressure levels

● ASME B16.9 – Stub ends available in Short and Long Pattern

● ASME SA 815 / SA 403 – Forged stainless steel for pressure and process piping

● ASME SB 366 – Special alloys for demanding environments

● End preparation per ASME B16.25

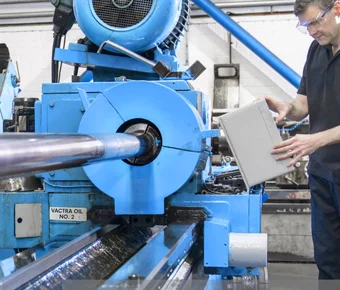

Collaring as a Forming Technique for Stainless Steel Pipes

Collaring of stainless steel pipes is a mechanical forming process in which the pipe end is flared and widened to allow for a tight, detachable connection with a collar flange or backing ring. This process requires precise material knowledge, suitable tools, and careful machining to ensure safety and performance. Depending on the application and material, different collaring angles (e.g., 37°) and shapes are used. Especially in industrial systems, this method is a proven alternative to welding.

Advantages of our Collar Solutions:

● High corrosion resistance thanks to selected special stainless steels

● Perfect fit for your application due to a wide range of materials

● Permanent stock availability across 12,000 m² warehouse space

● Fast delivery times and custom production possible

● All products come with comprehensive certification

- MSS-SP 43

- ASME B 16.9 short pattern/long pattern

- ASME SA 815/403

- ASME SB 366

- With chamfer according to ASME B 16.25

- MSS-SP 43

- ASME B 16.9 short pattern/long pattern

- ASME SA 815/403

- ASME SB 366

- With chamfer according to ASME B 16.25

Tables and rates

Haven’t found the right steel?

We offer you the complete range for stainless steel piping systems, in different materials and for the highest demands.