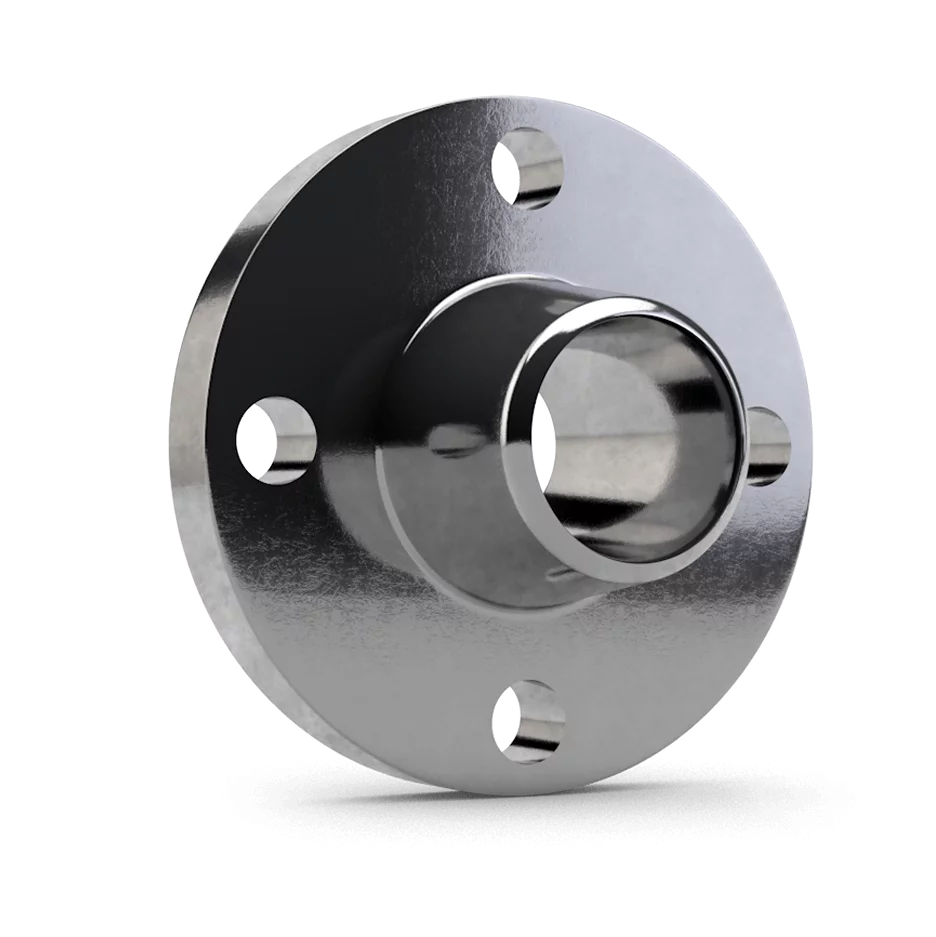

What are flanges and why are they essential in industry?

A flange is a ring-shaped connection element used to securely and tightly join pipelines, valves, or equipment components. It is typically welded or bolted to pipe ends or machinery. The major advantage: flanges create a detachable connection – ideal for maintenance, replacement, or extension of industrial piping systems.

Simply put, it’s a versatile component that plays a crucial role in every pipeline system where reliable connections matter.

What Is the Purpose of a Flange?

The purpose of a flange is to provide stability, tightness, and flexibility in pipeline systems. What is the purpose of a flange? It ensures that pipelines can be safely connected, separated, or extended – whether in the chemical industry, plant engineering, power generation, or offshore technology.

Certified Stainless Steel Flanges to EN 10204 and International Standards

WITTE TUBE supplies stainless steel flanges with all standard inspection certificates according to EN 10204 – including certificates to DIN EN, VdTÜV material sheets, ASME, or custom specifications. Additional testing to individual requirements – such as VdTÜV 418, VdTÜV 421, or NORSOK MDS D41 – is available at short notice.

Our Product Range – All Common Types of Flanges and Standards

Whether you’re looking for blind flanges, weld neck flanges, slip-on flanges (SO flanges), lap joint flanges, socket weld flanges, threaded flanges, or classic flange pipes – WITTE TUBE offers all key types of flanges in certified quality:

● EN 1092-1 / DIN EN 1092-1

● EN 1759-1

● ASME B16.5 (Industrial flanges ASME)

● DIN 2632, DIN 2514, DIN 2526, and many more

● Pressure ratings: PN10 / PN16 / PN40 / up to 1500 lbs (ASME)

All items are available in standard dimensions or as custom-made flanges for pipes, perfectly suited for your piping sections and systems.

Weld Neck Flanges (V-Flanges)

Our weld neck flanges comply with a wide range of national and international standards and specifications, including:

DIN Standards:

● DIN 2632, DIN 2633, DIN 2635

● DIN 2512, DIN 2513, DIN 2514, DIN 2526, DIN 2559

● DIN 2519 in combination with AD 2000 bulletins W2, W9, and W10

EN Standards:

● DIN EN 1092-1, Type 11A to 11H, PN10 / PN16 / PN40

VdTÜV Material Sheets:

● VdTÜV 418, VdTÜV 421

International Standards:

● NACE MR 0175

● NORSOK MDS D41

● ISO 15156-3

● ASME B16.5

● ASTM/ASME A/SA 182

● ASME Section II, Part A

Blind Flanges (B-Flanges / BL-Flanges)

Our blind flanges are designed for demanding applications and meet the following standards:

DIN Standards:

● DIN 2527 (PN10 / PN16 / PN40)

● DIN 2512, DIN 2513, DIN 2514, DIN 2526, DIN 2559

● DIN 2519 with AD 2000 W2 / W9 / W10

EN Standards:

● DIN EN 1092-1, Type 5A to 5H, PN10 / PN16 / PN40

VdTÜV Material Sheets:

● VdTÜV 418, VdTÜV 421

International Standards:

● NACE MR 0175

● NORSOK MDS D41

● ISO 15156-3

● ASME B16.5

● ASTM/ASME A/SA 182

● ASME Section II, Part A

Materials – Standard and Special Stainless Steels for extreme demands

Our warehouse stocks both standard stainless steel flanges and high-performance alloys for use in corrosive or extreme environments:

● 1.4539 904L – highly corrosion-resistant austenitic steel

● 1.4547 254SMO / S31254 – for aggressive media

● 1.4462 Duplex / S31803 / S32205 – austenitic-ferritic, stainless

● 1.4410 Super Duplex / S32750 – maximum corrosion resistance and strength,

- DIN 2632, 2633, 2635

- DIN 2512, 2513, 2514, 2526, 2559

- DIN EN 1092-1/ Typ 11A-H/PN10/16/40

- DIN 2519, AD 2000-W2/9/10

- VdTÜV 418

- VdTÜV 421

- NACE MR 0175

- NORSOK MDS D 41

- ISO 15156-03

- ASME B 16.5

- ASTM/ASME A/SA 182

- ASME Sec. II part A

- DIN 2527 PN 10/16/40

- DIN 2512, 2513, 2514, 2526, 2559

- DIN 2519, AD 2000-W2/9/10

- VdTÜV 418

- VdTÜV 421

- NACE MR 0175

- NORSOK MDS D 41

- ISO 15156-03

- ASME B 16.5

- ASTM/ASME A/SA 182

- ASME Sec. II part A

- DIN EN 1092-1/ Typ 5A-H/PN10/16/40

- AD 2000-W2/9/10

- ASME B 16.5

- 150/300/400/600/900/1500 lbs

- NACE MR 0175

- NORSOK MDS D 41

- ISO 15156-03

- ASTM/ASME A/SA 182

- ASME Sec. II part A

Tables and rates

Haven’t found the right steel?

We offer you the complete range for stainless steel piping systems, in different materials and for the highest demands.