Material Data Sheet and Technical Overview

The stainless steel grade 1.4571, also known as X6CrNiMoTi17-12-2, AISI 316Ti or SS 316 Ti, is an austenitic chromium-nickel-molybdenum stainless steel stabilized with titanium. The titanium addition improves resistance to intergranular corrosion by preventing the formation of chromium carbides during long-term exposure to temperatures between 450 and 850 °C. This makes 316Ti stainless steel especially valuable for welded constructions and thermally stressed components.

Standards and Identifications of Stainless Steel 1.4571

● EN: 1.4571

● DIN: X6CrNiMoTi17-12-2

● AISI: 316Ti

● UNS: S31635

Alternative designations include 316Ti material, 1.4571 stainless, EN 1.4571 stainless steel,

and X6CrNiMoTi17-12-2.

Material Profile: Stainless Austenitic Chromium-Nickel Steel

1.4571 / 316Ti is a stainless austenitic chromium-nickel steel with enhanced corrosion resistance, especially against pitting and in aggressive media. It shares core characteristics with standard 316, but thanks to its titanium stabilization, offers:

● Improved resistance to intergranular corrosion after welding

● High resistance to a broad range of organic and inorganic acids, even at elevated concentrations and temperatures

● Reliability in thermal cycling environments, where long-term exposure to medium temperatures is expected

● Similar pitting resistance as 316 (PREN 23.1–26.7), but not suitable for seawater exposure

1.4571 || 316Ti

- Good weldability

- High resistance to general corrosion

- Good resistance to intergranular corrosion

- Good cold formability

- High tensile strength

- Good forgeability

Typical Applications of EN 1.4571 Stainless Steel

The 316Ti stainless steel is frequently used where high corrosion resistance and thermal stability are critical, such as:- Plant and apparatus engineering

- Chemical and petrochemical industry

- Food processing industry

- Pipeline construction

- Mechanical engineering

- Building industry

- Nuclear technology

The 1.4571 material, or AISI 316Ti, is a titanium-stabilized austenitic stainless steel developed for demanding applications involving corrosive media, thermal cycling, and welded constructions. It offers reliable performance in a wide temperature range and shows enhanced resistance to intergranular corrosion compared to non-stabilized steels like 316L.

Thanks to its combination of mechanical and chemical properties, ss 316 Ti is a preferred material in various industrial sectors that require robust and durable stainless steel solutions.

Chemical Composition of 1.4571 Material

(weight proportion in %)

| Value | Proportion % |

|---|---|

| Carbon (C) | min. 0% - max. 0.08 % |

| Manganese (Mn) | min. 0% - max. 2.00 % |

| Silicon (Si) | min. 0% - max. 1.00 % |

| Phosphorus (P) | min. 0% - max. 0.045 % |

| Sulfur (S) | min. 0% - max. 0.030 % |

| Chromium (Cr) | 16.5 – 18.5 % |

| Nickel (Ni) | 10.5 – 13.5 % |

| Molybdenum (Mo) | 2.00 – 2.50 % |

| Titanium (Ti) | 5xC – 0.70 % |

Mechanical Properties at 20 °C

| Hardness (HB) | ≤ 215 |

| Yield strength (Rp₀.₂) | ≥ 200 N/mm² |

| Tensile strength (Rm) | 500 – 700 N/mm² |

| Elongation (A5,65) | ≥ 40 % |

| Elastic modulus | 200 kN/mm² |

Physical Properties of 316Ti Stainless Steel

| Density | 8.0 kg/dm³ |

| Electrical resistance | 0.75 Ω·mm²/m |

| Thermal conductivity | 15 W/m·K |

| Specific heat capacity | 500 J/kg·K |

| Magnetizability | non-magnetic |

Temperature Behavior and Heat Resistance

Stainless steel 1.4571 is designed for operation up to 550 °C and is also suitable for cryogenic conditions. Thanks to the titanium content, it resists carbide precipitation and maintains corrosion resistance even after long-term thermal stress.

| Solution annealing | 1020 – 1120 °C (cooling in water or air) |

| Hot forming | 1200 – 900 °C (cooling in air) |

| Service temperature range | cryogenic to 550 °C |

- Designation according to DIN: X 6 Cr Ni Mo Ti 17

- ASTM Grade: 316 Ti

- EN: 1.4571

- ASME: 316 Ti

- AFNOR: X6CrNiMoTi 17-12-2

- DIN: 1.4571

- SIS: 2350

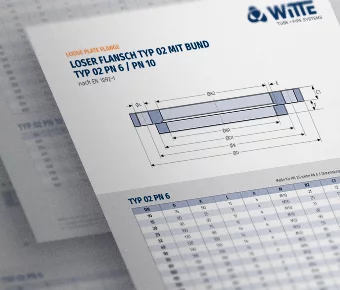

Tables and rates

Haven’t found the right steel?

We offer you the complete range for stainless steel piping systems, in different materials and for the highest demands.