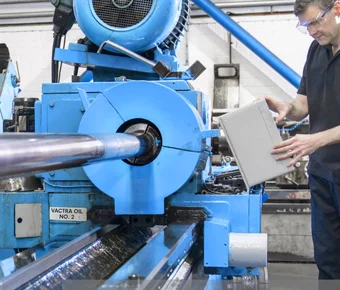

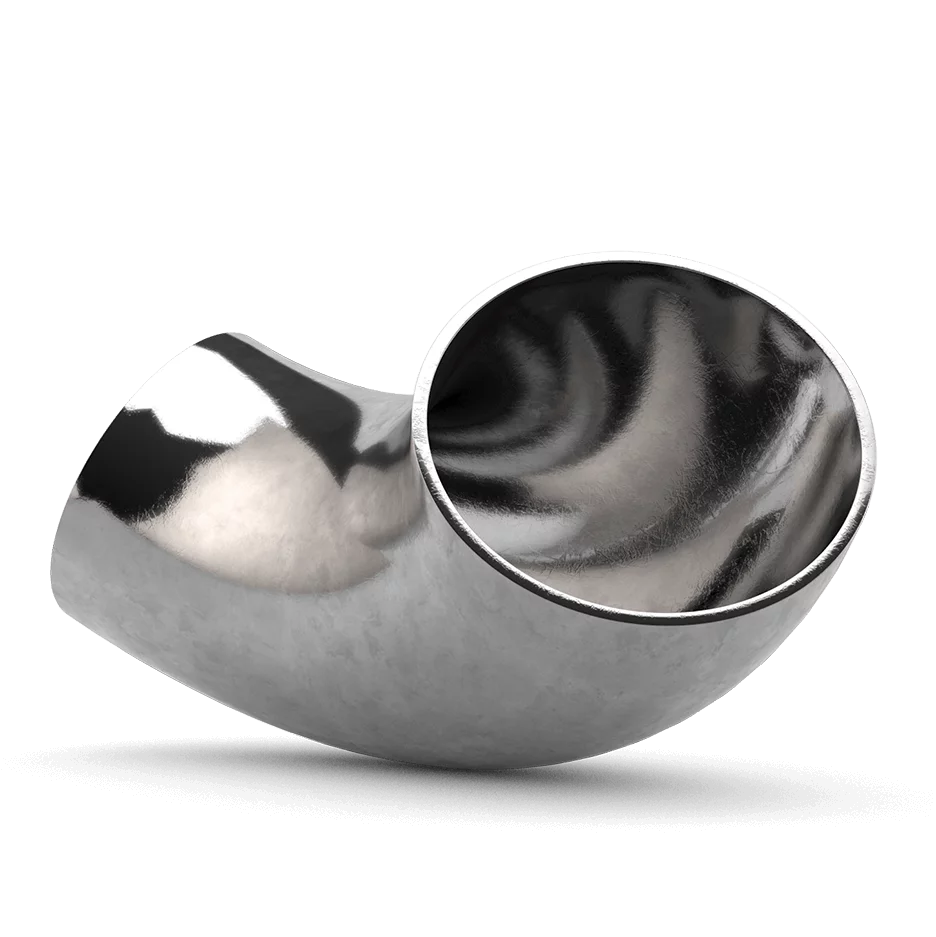

Stainless Steel Elbows – Properties and Dimensions

Pipe elbows are essential components in industrial piping systems. Whether for space-saving installations, flow-optimized systems, or complex plant setups – stainless steel elbows ensure stable, durable, and leak-proof connections.

Materials & Designs – Versatile and Reliable

We offer stainless steel pipe elbows in both seamless and welded designs, tailored to your specific requirements. Our extensive stock includes elbows made from high-quality stainless steels, including:

● 1.4541 – Stable and temperature-resistant, widely used in chemical and process industries

● 1.4462 (Duplex Steel) – Excellent corrosion resistance and mechanical strength

● 1.4410 (Super Duplex Steel) – Highly resistant to aggressive media like chlorides and seawater

Depending on your application, we supply elbows made from austenitic stainless steel, duplex or super duplex grades, as well as heat-resistant special alloys.

Standards & Quality – DIN 2609 and More

WITTE TUBE and WITTE HiTEMP supply stainless steel elbows that comply with all relevant international standards and technical specifications, including:

● DIN 2605-1 / DIN 2605-2, DIN 2609

● EN 10253-4, EN 10253-3

● AD 2000 W2 / W10

● VdTÜV 1252, 418, 421

● ASME B16.9, ASTM/ASME A/SA 815 / 403

● DIN 2559-22 (from 3 mm wall thickness), ASME B16.25 (bevel preparation)

Advantages of Stainless Steel Pipe Elbows

● High corrosion resistance

● Pressure and temperature resistant

● Long service life

● Hygienic and low-maintenance

● Ideal for aggressive or sensitive media

Whether you need a stainless steel 90 degree elbow for a tight bend or a 45 degree pipe elbow for smooth directional flow – we deliver the right solution for your system.

What Bending Radii Are Available?

We supply elbows in various radii and designs:

● BA2 / SR – Short radius

● BA3 / LR – Long radius

● BA5 – Segment elbows

The key difference between long radius and short radius elbows lies in the bend radius – which affects the elbow’s shape, installation space, and flow characteristics.

| Criterion | Long Radius Elbow (LR) | Short Radius Elbow (SR) |

| Bend Radius ® | 1.5 × outside diameter (R = 1.5 × D) | 1.0 × outside diameter (R = 1.0 × D) |

| Designation | LR (Long Radius) | SR (Short Radius) |

| Space Requirement | Higher – requires more space for the bend | Compact – ideal for tight installation areas |

| Flow Behavior | Optimized – less pressure loss | Higher turbulence and potential pressure loss |

| Impact on Medium | Gentler on flow, ideal for fast or aggressive media | Increased stress due to sharper redirection |

| Typical Applications | Chemical, pharmaceutical, plant construction | Compact piping systems, limited installation space |

- DIN 2605-1/-2

- DIN 2609

- EN 10253-4

- EN 10253-3

- AD 2000-W2

- AD 2000-W10

- VdTÜV 1252

- VdTÜV 418

- VdTÜV 421

- ASME B 16.9

- ASTM/ASME A/SA 815/403

- DIN 2559-22 from 3 mm wall thickness/ASME B 16.25 (chamfer)

Tables and rates

Haven’t found the right steel?

We offer you the complete range for stainless steel piping systems, in different materials and for the highest demands.