Duplex Stainless Steel 1.4462 (S31803 / S32205): Material Overview and Technical Datasheet

The material 1.4462, also referred to as duplex stainless steel, duplex 2205, UNS S31803, or F51 duplex, is a nitrogen-alloyed, two-phase stainless steel combining both austenitic and ferritic characteristics. It belongs to the category of duplex stainless steel grades and offers significantly higher mechanical strength and corrosion resistance compared to standard austenitic stainless steels such as 304 or 316.

The balanced microstructure of ferrite and austenite results in excellent performance against stress corrosion cracking, general corrosion, and pitting. Due to its high strength and economical nickel content, duplex ss materials like stainless 2205 are widely used in challenging industrial environments and are valued for their cost-efficiency.

Key Properties of Duplex Stainless Steel

- Higher tensile and yield strength compared to conventional austenitic stainless steel

- Excellent resistance to pitting and crevice corrosion (PREN ≥ 35)

- High resistance to stress corrosion cracking

- Strong performance in acidic media and chloride-containing environments

- Good weldability without risk of intergranular corrosion

- Economically favorable due to reduced nickel content

Special stainless steel

Corrosion Resistance of Duplex Stainless Steel 1.4462

Duplex stainless shows high corrosion resistance across a wide range of media, especially in chloride-rich and acidic environments. Thanks to its two-phase structure and alloy composition, it performs reliably in applications where both pitting and stress corrosion cracking are concerns.

- PREN value: 30.9 – 38.0

- Suitable for aggressive chemical conditions, marine atmospheres, and acidic process media

- Outperforms austenitic grades like 316L in terms of resistance to localized attack

Applications of Duplex SS (S31803 / S32205 / 1.4462)

- Chemical and petrochemical plants

- Pulp and paper industry

- Offshore structures and shipbuilding

- Flue gas desulfurization systems

- Desalination and seawater treatment plants

- Heat exchangers and pressure vessels

- Structural components in corrosive environments

Chemical Composition of S31803 Material

(weight proportion in %)

| Value | Proportion % |

|---|---|

| Carbon (C): | ≤ 0.03% |

| Manganese (Mn): | ≤ 2.00% |

| Silicon (Si): | ≤ 1.00% |

| Phosphorus (P): | ≤ 0.035% |

| Sulfur (S): | ≤ 0.015% |

| Chromium (Cr): | 21.00 – 23.00% |

| Molybdenum (Mo): | 2.50 – 3.50% |

| Nickel (Ni): | 4.50 – 6.50% |

| Nitrogen (N): | 0.10 – 0.22% |

Mechanical Properties of SS 2205 Material at Room Temperature

The elastic limit of duplex steel is about 150% higher compared to standard austenitic grades like 1.4301 or 1.4404”, contributing to lighter and more efficient component design.

| Tensile strength: | 650 – 880 N/mm² |

| Yield strength: | ≥ 450 N/mm² |

| Elongation: | ≥ 25% |

| Hardness (HB): | ≤ 270 |

| Elastic modulus: | 200 kN/mm² |

Physical Properties at 20 °C

| Density: | 7.8 kg/dm³ |

| Thermal conductivity: | 15 W/m·K |

| Specific heat capacity: | 500 J/kg·K |

| Electrical resistance: | 0.80 Ω·mm²/m |

| Magnetizability: | present |

Designations and International Standards of Duplex 2205

| EN: | 1.4462 |

| DIN: | X2CrNiMoN 22-5-3 |

| UNS: | S31803 / S32205 |

| ASTM grade: | S31803 / S32205 |

| ASME: | Duplex |

| AFNOR: | X2CrNiMoN 22-5-3 |

| SIS: | 2377 |

| Vd TÜV: | 1.4462 |

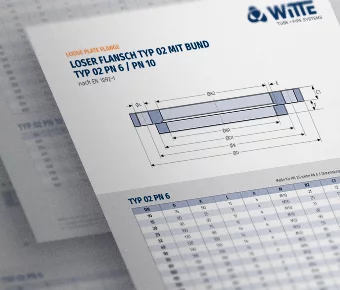

Tables and rates

Haven’t found the right steel?

We offer you the complete range for stainless steel piping systems, in different materials and for the highest demands.